In order to provide reliable turnkey solutions to diverse markets, we have combined the optimum capability of medium and large size CNC machines for turning, milling, along with welding and cladding capabilities with the upmost qualified personnel.

Capabilities

Rough Turning

Up to 76″ diameter & 28′ long on lathes

Up to 150″” diameter & 123″ high on vertical turret lathes

Up to 100,000 lbs.

Inspection

100% Final inspection on all machined areas

95% First pass acceptance

In house NDE to include PT, LP, MT, UT, with ASNT Level III Supervision

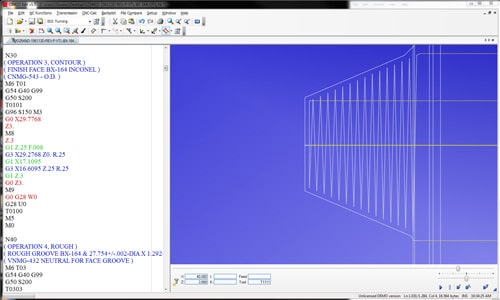

Technology

To meet your specifications with exact precision and to avoid costly errors, our in-house engineering staff verifies all customer drawings for accuracy before manufacturing. We rely on state-f-the-art software and 3D modeling to ensure manufacturing perfection:

Soliworks

GibbsCAM

EdgeCam

CIMCO Edit

Gagemaker

Turnkey Solutions

100% Final Inspection on all machined areas

95% First pass acceptance

In house NDE to include PT, LP, MT, UT, with ASNT Level III Supervision