Machining Capabilities

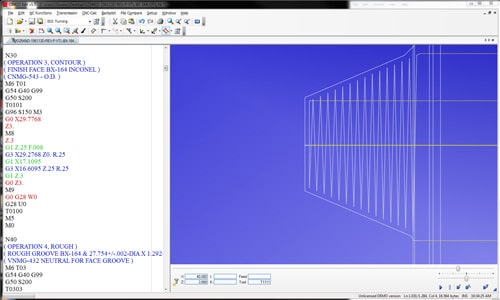

In order to provide reliable turnkey solutions to diverse markets, we have combined the optimum capability of medium and large size CNC machines for turning, milling, along with welding and cladding capabilities with the upmost qualified personnel.

Our machining capabilities enable us to tackle even the most complex projects with precision and efficiency, handling everything from intricate custom components to large-scale production runs, all while supporting a wide range of industries and applications.