Materials

Materials

We use following Materials for forging and heat treating:

- Carbon & Alloy Steel – 20 pounds to 8,000 pounds

- Stainless Steel – 20 pounds to 8,000 pounds

- Nickels – 20 pounds to 3,500 pounds

- Titanium – 20 pounds to 3,500 pounds

Materials

MaterialsWe use following Materials for forging and heat treating:

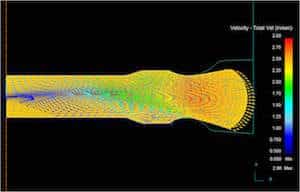

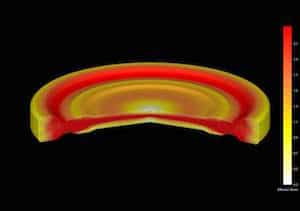

Technology is the key to maintaining a competitive edge and differentiating Ellwood Texas Forge from the other forgers in the industry. Our engineers have several tools at their disposal to enhance their productivity and ensure first run success on new products.

Modeling:

Modeling:

A full range of high speed CNC machining centers are employed in the manufacture of dies weighing from 200 LBS to 40000 LBS. Repeatability is guaranteed during die refurbishment (required for serial, production) with our direct CNC die sinking techniques. ECDG offers the fastest time to market by employing customer 3D files or by relying on extensive in